AS ISO 10545.3 pdf download

AS ISO 10545.3 pdf download.Ceramic tiles

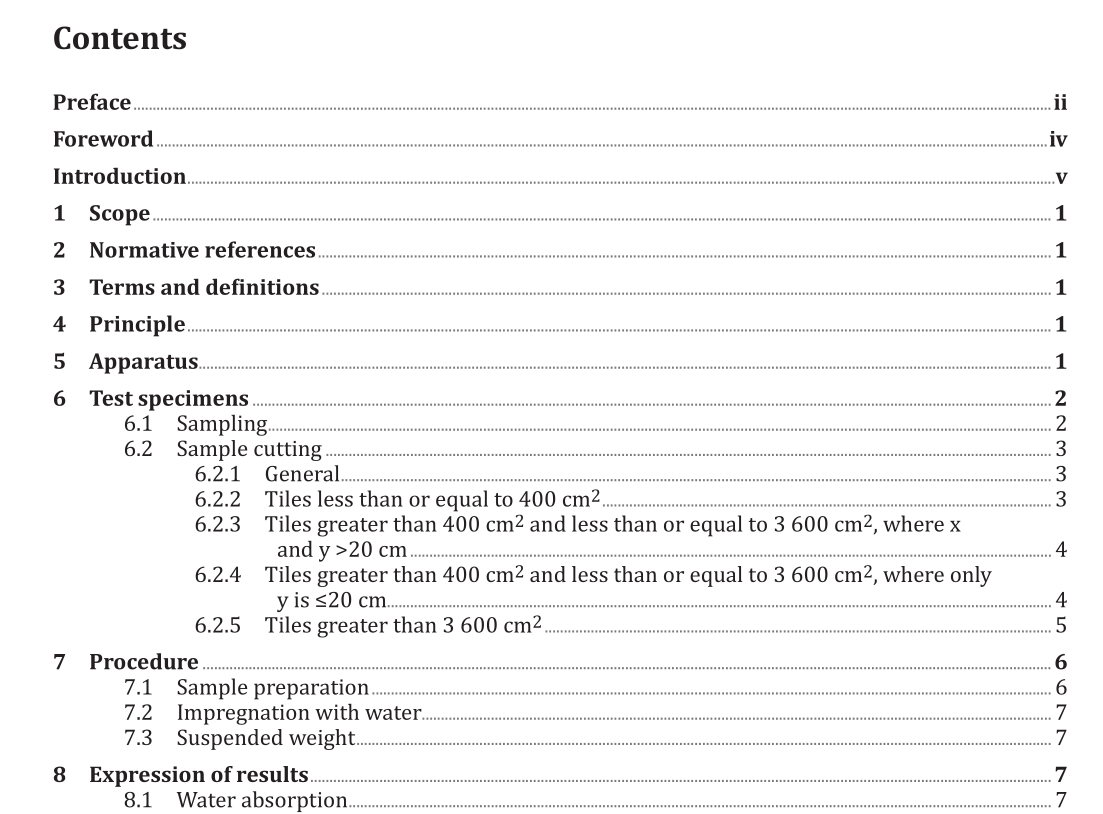

1 Scope

This document specifies a method for determining water absorption, apparent porosity, apparent relative density and bulk density of ceramic tiles. This method is applicable to classification of tiles and product specifications.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

No terms and definitions are listed in this document. ISO and IEC maintain terminological databases for use in standardization at the following addresses: — IEC Electropedia: available at http:// www .electropedia .org/ — ISO Online browsing platform: available at https:// www .iso .org/ obp

4 Principle

Impregnation of dry tiles with water and then suspension in water. Calculation of the listed properties using the relationships between dry, saturated and suspended masses.

5 Apparatus

5.1 Drying oven, capable of being operated at least at (110 ± 5) °C. Microwave, infrared, or other drying systems may be used provided that it has been determined that the same results are obtained. 5.2 Balance, accurate to 0,01 % of the mass of a test specimen. 5.3 Deionized or distilled water 5.4 Dessicator 5.5 Microfibre cloth 5.6 Wire loop, halter or basket, capable of supporting specimens under water for making suspended mass measurements. 5.7 Glass beaker, or similar container of size and shape such that the sample, when suspended from the balance (5.2) by the wire loop (5.6), is completely immersed in water, with the test specimen and the wire loop being completely free of contact with any part of the container.5.8 Vacuum chamber and vacuum system, of sufficient capacity to accommodate the test specimens and evacuate to a pressure of 10 ± 5 kPa (91 ± 5 kPa below standard atmospheric pressure of 101 kPa) for 30 min.

6 Test specimens

6.1 Sampling Sampling shall be carried out according to the dimension of tiles as reported in Table 1. In Table 2 some examples of different common sizes are reported. The number of the specimens to be tested for each tile as well the number of tiles are function of the tile dimension. Tiles and relevant specimens shall not contain visible damage or cracks prior to testing and shall not have been previously tested. Any loose or contaminating material shall be removed. This includes any mesh, paper and adhesive that has been applied to mosaics. When the mass of each individual tile is below 50 g, a sufficient number of tiles shall be taken so that each test specimen reaches a mass of 50 g to 100 g. For those specimens, 6.2 is not applicable.6.2 Sample cutting 6.2.1 General Each tile shall be cut into smaller pieces as described in 6.2.2 through 6.2.5 where some common examples are reported. Cutting of specimens shall consist of scoring and snapping, or sawing when impossible to score and snap with conventional tile-scoring equipment (as can be the case with highly textured and structured porcelain tiles). Cutting may be performed at the factory following the sampling criteria described where the sample being cut is at least 10 cm bigger on each cut side. At the testing facility, cutting shall be done no more than four hours before the specimens are placed in the dryer. Specimens shall be kept clean with no contaminating material after cutting. 6.2.2 Tiles less than or equal to 400 cm 2 Specimens shall be cut in half, within 1 cm. Specimens shall be cut perpendicular to the longest side if the specimen has unequal sides. Select one half at random from each specimen for testing (see Figure 1).

7 Procedure

7.1 Sample preparation Dry the test specimens to constant mass (see NOTE) in the oven (5.1) adjusted to a minimum of 110 °C, not to exceed 160 °C for a minimum of 24 h (or such other time as has been established for the oven in use and the mass of tiles being dried). The drying of the specimens and the determination of their masses may be done either before or after the specimens have been impregnated with water. Usually the dry mass is determined before impregnation. However, if the specimens are friable or evidence indicates that particles have broken loose during the impregnation, the specimens shall be dried and weighed after the suspended mass and the saturated mass have been determined. In this case, the second dry mass shall be used in all appropriate calculations. NOTE Constant mass is reached when after two subsequent weightings, the final weight does not change more than 0.1 %. Specimens being tested directly following their manufacture can be considered fully dried so long as they have not been subjected to any process that wets the specimen post firing (such as can occur in cutting and polishing operations), and they are placed in a desiccator sufficiently quickly (usually within no more than 30 min of exiting the kiln) that no moisture has been absorbed from ambient air, as can be confirmed by weighing to constant mass after impregnation.